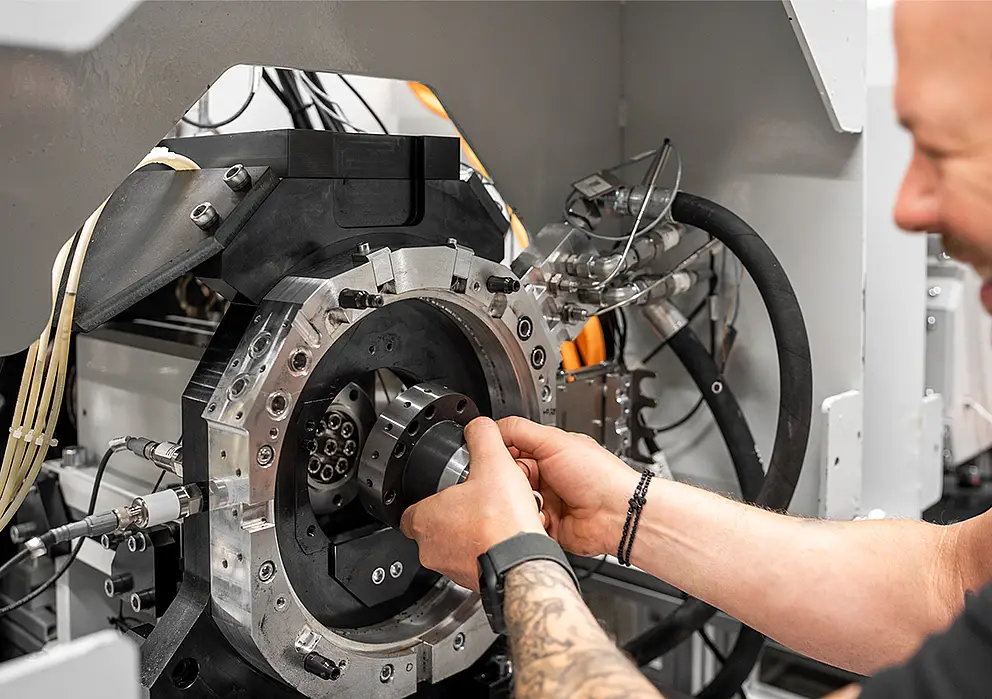

Mechanics, electrics & hydraulics

Safety for every part

Whether in individual tests or as part of a complex system - every component has a decisive influence on performance and reliability. Using state-of-the-art testing technology and practical scenarios, we safeguard your components before they can fail in the overall system.

Reliability starts with the detail.

Precise tests for every component

Whether bearing, sensor, actuator or housing: every component must function perfectly under load and in interaction with others. PTS-Prüftechnik offers component-specific tests for mechanical, electrical and hydraulic components - with realistic load profiles, precise measurement technology and digital evaluation. So that you know exactly how your components will perform in an emergency.

Multidisciplinary testing - precisely configured

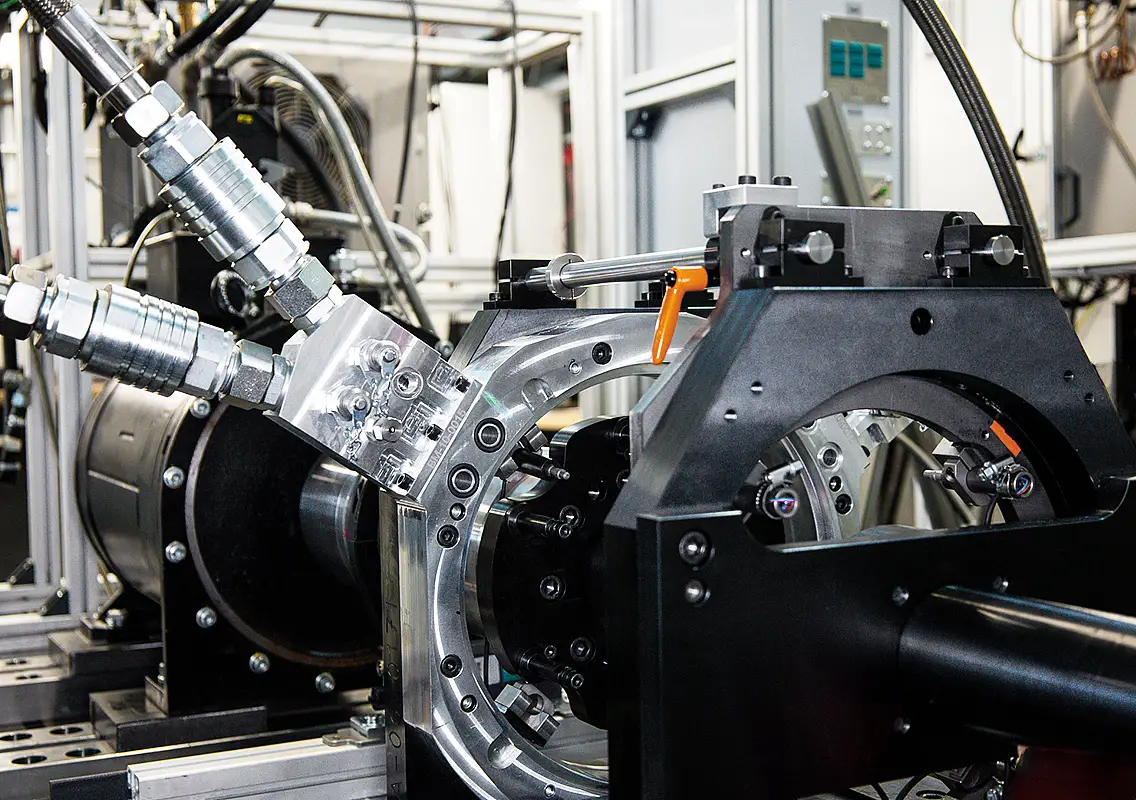

Our test benches combine mechanical, electrical and hydraulic loads in one system - ideal for endurance running, function, wear and safety.

Scope of services:

- Vibration, impact and pressure tests

- Thermal tests (temperature changes, climate profiles)

- Torque, friction and wear analyses

- High-voltage, insulation and EMC pre-tests

- Leakage, pressure pulse and combination tests

- NVH assessments (noise & vibration)

Test your components under all relevant conditions - with maximum informative value.

Flexible for every requirement

Test specimens & infrastructure at a glance

Typical test specimens:

Our tests cover a wide range of components:

- E-machines (rotor, stator)

- Drive train components (shafts, bearings, couplings)

- Control units, sensors, actuators

- Power electronics (inverters, relays)

- Housings, connectors, seals

- Valves, pumps, hydraulic lines, pressure accumulators

Technical infrastructure:

We rely on modular test environments for precise results:

- Modular configurable test benches

- Automated testing and evaluation systems

- Climatic chambers (-70 °C to +240 °C)

- Highly flexible integration of additional systems & units

- In-house production for special adapters & test parts

Advantages

Holistic system testing

Real test conditions

Customized tests & analyses

Everything from a single source

Component diagnosis, diagnostics & optimization

Analyze, optimize and safely commission HV components >

Read moreAssemblies & components in powertrain testing

More than individual components

Assembly and component tests are just one part of our powertrain portfolio. We test complete systems - from individual components to entire drive units - under realistic conditions and with intelligent monitoring.

Explore the full Powertrain Testing portfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.