FEM simulation for resilient structures

Check structures. Gain security.

From the individual component to the overall structure - we use FEM simulations to analyze strength, vibrations and service life. Precise, standard-compliant and practical to make your designs safe and efficient.

Mechanics, dynamics, thermals - precisely calculated

FEM simulation for reliable design and protection

The finite element method (FEM) is a powerful tool for designing and validating mechanical systems. We use FEM simulations to evaluate strength, vibration behavior, service life and thermal effects - realistically and in compliance with guidelines. Whether vehicle components, mechanical engineering or battery technology: we provide reliable answers to your design questions and safeguard your product development - efficiently and in compliance with standards.

Our simulation solutions at a glance

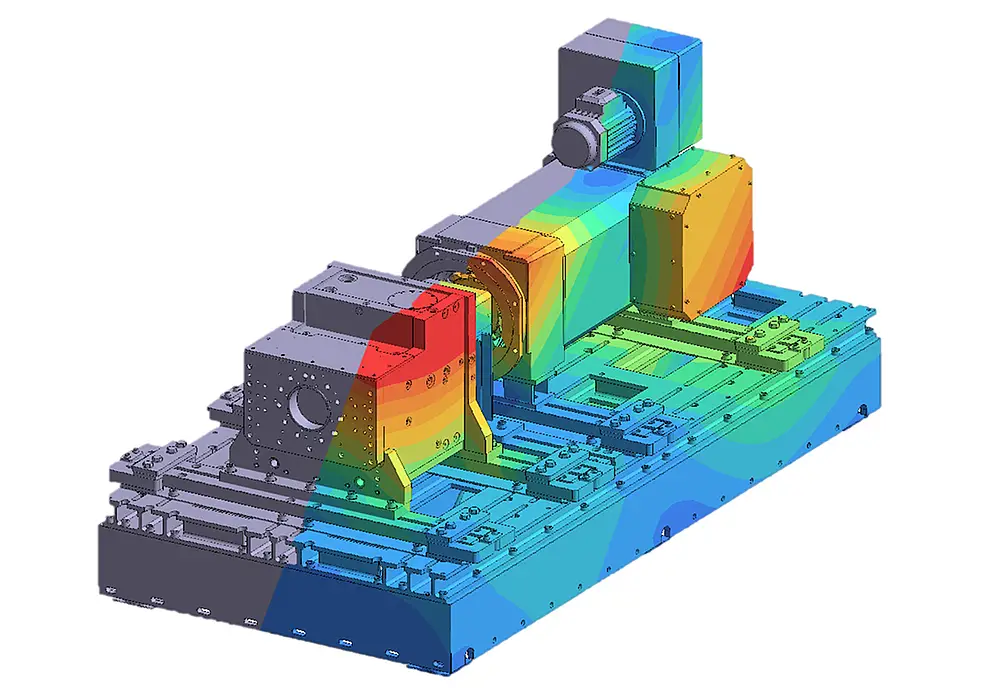

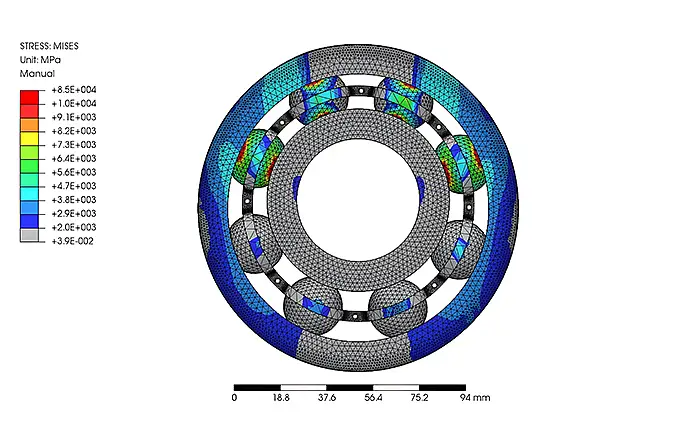

We check the load-bearing capacity and safety of welded and non-welded components and assemblies. Based on the CAD geometry, we use state-of-the-art simulation software to generate an optimized finite element mesh and calculate stresses and deformations under realistic boundary conditions. The results provide reliable proof of component safety - precisely, efficiently and in accordance with standards.

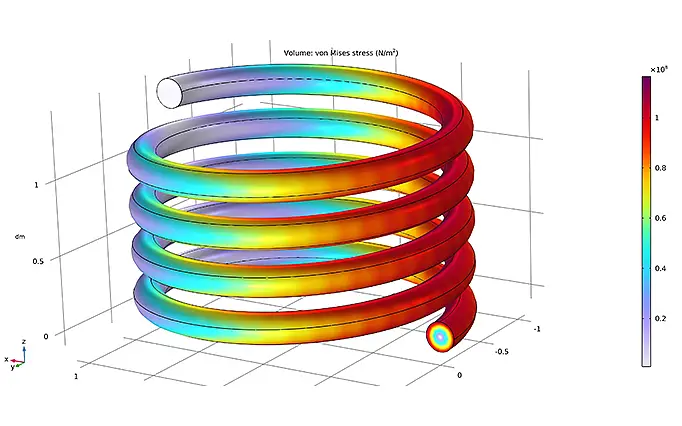

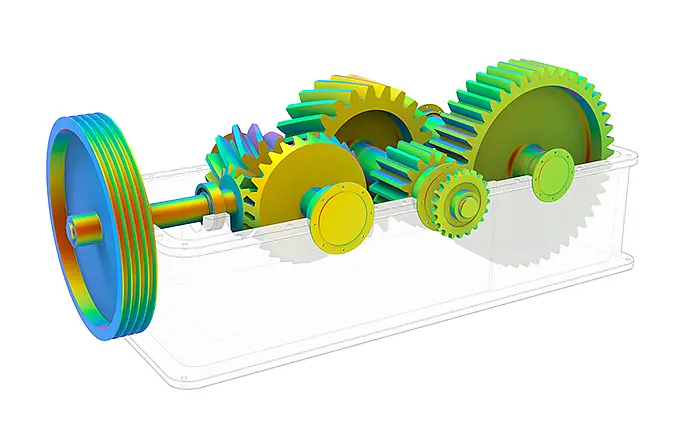

We analyze vibrations and dynamic load cases, from natural frequencies and modes to transient processes. This allows time-dependent stresses, deformations and contact forces to be simulated - for example in moving or vibrating assemblies. This allows us to identify resonance cases, minimize the risk of damage and ensure the safety of dynamically stressed systems.

We use MKS to simulate the movement and load of complex mechanisms. Joints, bearings and connections are modeled in detail with regard to forces, friction and displacements. Inertia and elasticity effects are incorporated realistically. In this way, movement profiles can be optimized, critical load peaks reduced and the function of kinematics ensured.

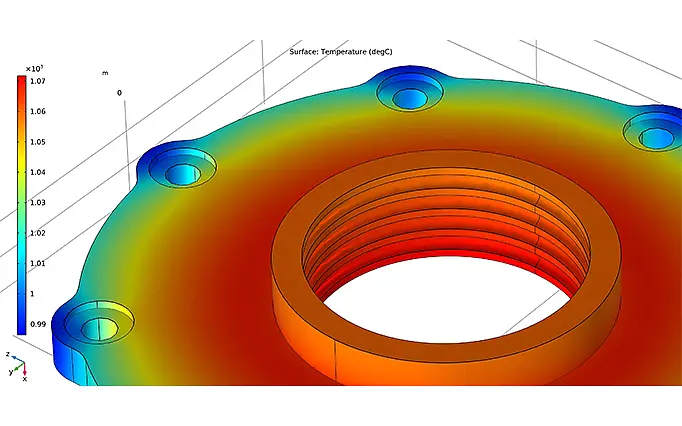

We calculate both steady-state and transient temperature distributions in individual components and complex assemblies. Based on these results, we couple heat flow and mechanical stresses in order to reliably predict temperature-induced deformations, residual stresses and service life influences. In this way, we support you in safely designing thermally stressed constructions, avoiding hot spots and sustainably increasing the performance of your product.

We evaluate the fatigue strength of steel, cast iron and aluminum components under cyclic loading. Based on the material-specific Wöhler characteristic curves and the specific load spectra, we calculate the degree of utilization and the expected service life in accordance with the FKM guideline. This provides you with a reliable basis for decision-making in order to identify critical areas, optimize designs and reliably avoid operational failures.

We increase the efficiency of your components with parameter studies, sensitivity analyses and topology optimizations. In doing so, we uncover the decisive influencing variables in order to reduce material and weight - without compromising on performance or safety. The result: technically and economically optimized components.

Our FEM analyses are carried out in accordance with the relevant standards and thus ensure reliable, recognized verifications:

- FKM guideline for static and dynamic strength

- VDI 2230 / DIN 912 for the design of bolted connections

Typical fields of application

Our FEM simulations ensure the mechanical performance of your components and assemblies - digitally, precisely and in compliance with standards.

- Automotive industry: structure, crash, vibration

- Mechanical engineering: kinematics, bearings, heat

- Energy technology: housings, brackets, load cases

- Aerospace: lightweight construction, service life

- Battery technology: cell holder, contacting, crash

Safety right from the start

We support your development from the concept phase through to series production. Our FEM models provide decisive indications of hot spots, weak points or potential at an early stage - and thus enable a well-founded, guideline-compliant design.

Advantages

Fast & reliable results

From the component to the complete system

Seamless connection of simulation & test

Everything from a single source

Assemblies & components

Mechanical, electrical and hydraulic tests for a wide range of applications >

Read moreFEM simulation as part of our simulation world

Holistic protection of mechanical systems

FEM simulation complements 1D, CFD and casting methods and provides in-depth insights into structure, dynamics and thermomechanics. This allows components to be precisely evaluated in terms of strength, service life and load. Together with our other simulation focal points, the result is holistic digital validation - from the concept phase through to series production.

Explore the full Simulation portfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.