1D simulation for efficient development

Understanding systems. Avoid risks.

We use 1D simulation to analyze physical systems quickly and efficiently - thermally, electrically or in terms of control technology. This allows us to compare variants, validate scenarios and optimize products at an early stage - with minimal computing effort and high informative value.

Capture physical systems in real time

Efficient, robust and economical solutions with 1D simulation

1D simulation enables the fast and efficient analysis of physical systems - from thermal management and electrical wiring systems to control technology. The combination of detailed modelling, short computing time and high informative value makes it possible to compare variants, examine scenarios and optimize systems at an early stage. PTS-Prüftechnik offers you customized simulation models that reflect real conditions and reduce development costs.

Our simulation solutions at a glance

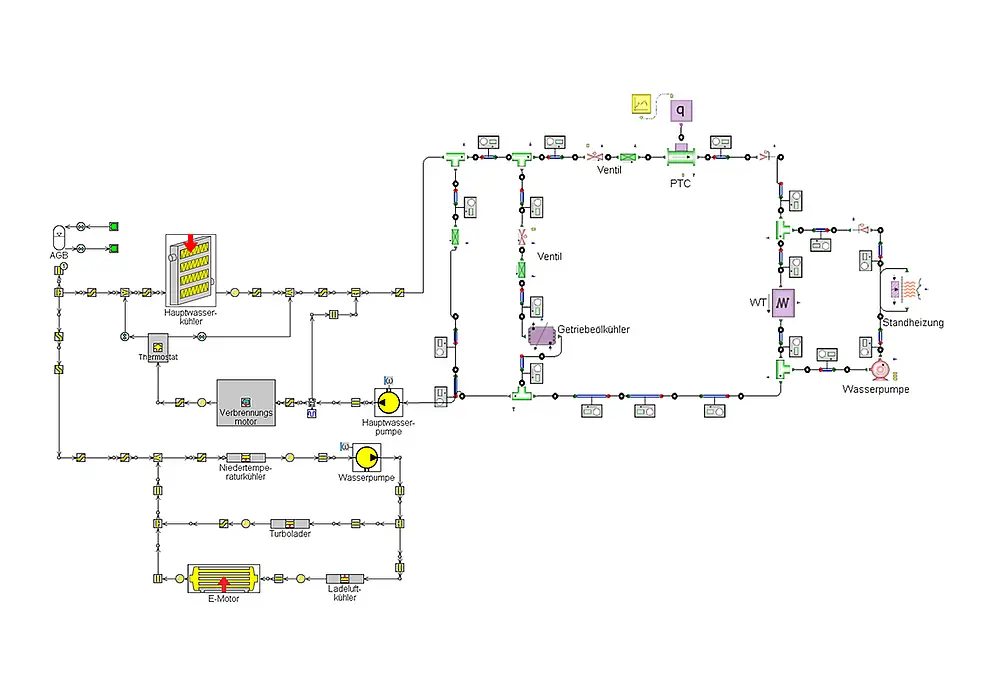

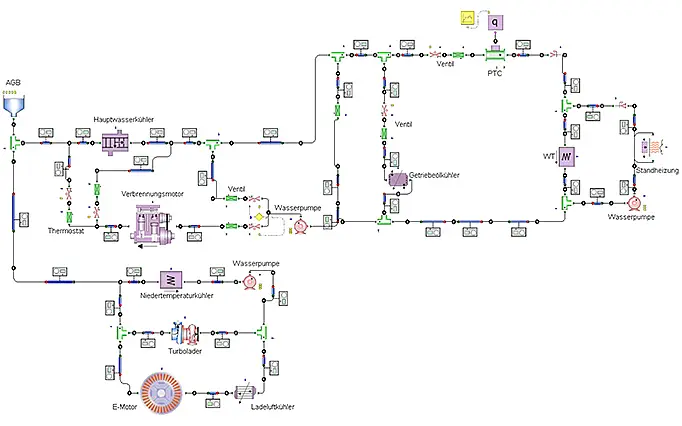

Based on 3D CAD data or hydraulic-thermal functional diagrams, we model complete cooling circuits, including pressure losses, mass flows, temperature curves and energy flows. This enables well-founded decisions to be made when designing, dimensioning and optimizing thermal systems - e.g. in vehicles, power electronics or mechanical engineering.

Our simulations virtually model electrical components such as cables, fuses, relays or inverters. This allows on-board electrical systems to be analyzed under real operating conditions and designed for static and dynamic scenarios - such as voltage dips, load peaks or faults. We provide you with targeted support in the development of robust, energy-efficient and standard-compliant electrical systems.

We model and simulate control and regulation systems in conjunction with physical plant models for the holistic analysis of mechatronic systems. With the help of 1D simulation methods, digital and analog control algorithms, logical processes as well as sensor and actuator concepts can be virtually mapped and coupled in real time with the associated mechanical, electrical or thermal systems. This allows control behaviour, system stability and response behaviour to be optimized at an early stage - e.g. for PID, state or model-based controllers.

Digital models for complex systems and real challenges

Fields of application at a glance

Whether vehicle technology, electronics or energy systems - our models help to understand systems realistically and to make development processes faster, more precise and more cost-efficient.

- Vehicle technology: thermal systems, vehicle electrical systems, control systems

- Power electronics: cooling concepts, load profiles

- Industrial automation: process control, energy flows

- Energy technology: storage and distribution networks Mechanical engineering: fluidics, pumps, valves

Flexible in the development process

Our 1D models can be flexibly integrated into your development phases - from preliminary design and variant optimization to near-series validation. They enable a well-founded system evaluation with minimal computing effort - even in combination with trials and tests.

Advantages

Fast & reliable results

From component to complete system

Seamless connection of simulation & test

Everything from a single source

1D simulation as part of our simulation world

Models that make systems understandable.

1D simulation is a central component of our simulation services. It complements CFD, FEM methods and casting simulation and creates transparency in early development phases - quickly, efficiently and practically. Together with the other simulation focal points, it forms the basis for holistic digital validation.

Explore the full Simulation portfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.