Electric, hybrid or conventional

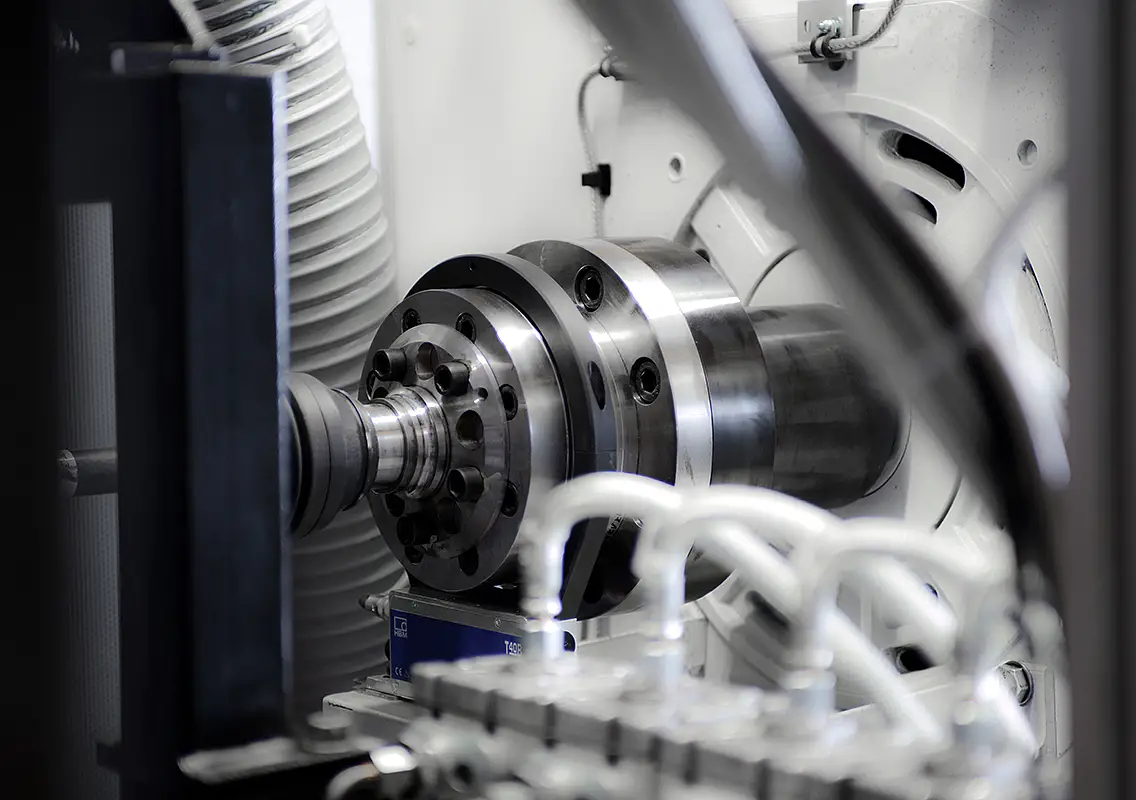

Precision for drive systems

From the energy source to the last cogwheel - modern drive units are a complex interplay of mechanics, electronics and software. With real or simulated energy storage systems, precise measurement technology and practical load profiles, we ensure performance, efficiency and reliability - at every stage of development.

Reliably securing complex systems

Real drive testing starts with the overall system

From the electric motor to the inverter, from the gearbox to the software: modern drive units are highly complex systems. PTS-Prüftechnik validates all components in interaction - realistically, flexibly and with intelligent monitoring. Our adaptable test benches provide meaningful data for your approvals - reliable, traceable and right from the pre-development stage.

Fully automated - from prototype to series production

Our test benches enable functional tests, thermal and mechanical loads as well as software analyses - automated, reproducible and meaningful.

Scope of services:

- Functional & endurance tests

- Accredited test laboratory for certification measurements (UN-ECE, GBT, etc.)

- Efficiency analyses & power loss measurements

- Thermal characterization & NVH analyses

- Load profile simulations (speed, temperature, driving cycles)

- Validation of protective functions & diagnostic algorithms

- Functional safety (FuSi)

- Communication tests (CAN, LIN, Ethernet)

- Battery, fuel cell or HIL simulation

Test your drive unit in a real scenario - with measurable safety.

Test benches, simulation & software

Front, rear or all-wheel drive | electric, hybrid or conventional

- Power up to 1,200 kW per axle

- Automated load management & energy recovery

- Temperature management & cooling circuit simulation

HIL simulation or real HV components

- Battery simulation with dynamic profiles

- Real-time behavior for voltage, current & temperature

- Fuel cell integration with stack simulation

Developed & integrated in-house

- Live monitoring & control

- Reproducible test sequences

- Intelligent result analysis incl. trend & error detection

Advantages

Holistic system testing

Real test conditions

Customized tests & analyses

Everything from a single source

Drive units as the core of powertrain testing

Holistic testing from the part to the system

Drive units are a central element of our powertrain portfolio. In addition to complete systems, we also test power electronics, mechanical components and drivetrains. We ensure efficiency, dynamics and reliability under real-life conditions - from early development to series release.

Explore the full Powertrain Testing PortfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.