Safety, efficiency and speed for every development

Simulation - thinking ahead virtually

Simulation makes developments faster, safer and more efficient. From battery cells to complete systems, from mechanical components to thermal extremes: With modern simulation methods, we create digital security for you long before your components reach the test bench.

Simulation makes developments efficient and resilient

Virtual protection as the key

At PTS-Prüftechnik, simulations complement real testing. We use state-of-the-art tools to precisely calculate structures, flows and systems. This allows concepts to be validated, weak points to be identified at an early stage and development times to be shortened. Simulation is not a substitute, but an amplifier: it makes tests more efficient and results more robust.

Advantages

Greater efficiency

Early validation

Reliable forecasts

Maximum security

Simulation as the key to efficiency

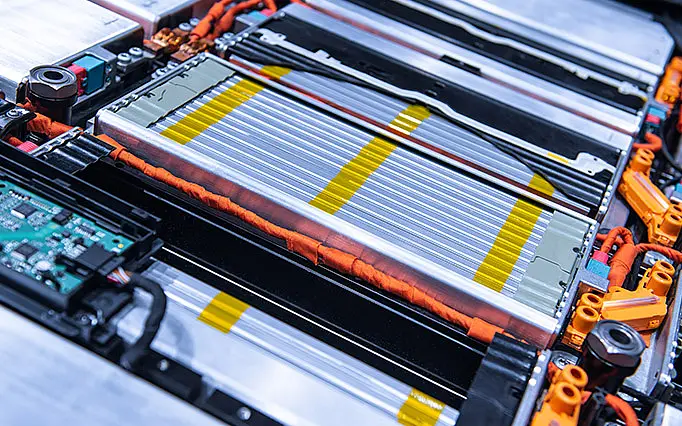

We simulate electrochemical processes and thermal properties at cell level. This allows us to predict ageing, performance and safety — before physical tests begin.

Read more

We analyze the interactions of individual cells in the module virtually. Flow and heat calculations provide valuable insights for stable thermal management and a balanced load.

Read more

We simulate complete systems under realistic conditions - from electrical load profiles to temperature cycles. The result: reliable concepts that can be robustly and efficiently implemented in practice.

Read more

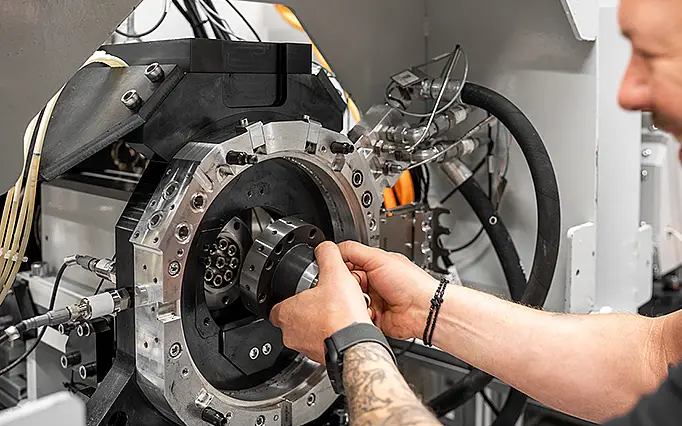

We simulate mechanical loads and thermal effects in clutch and brake systems. This allows us to predict and optimize wear, safety and service life in a targeted manner.

Read more

Whether housings, bearings or connecting elements: We use FEM analyses to evaluate strength, vibrations and service life - for resilient structures and short development cycles.

Read more

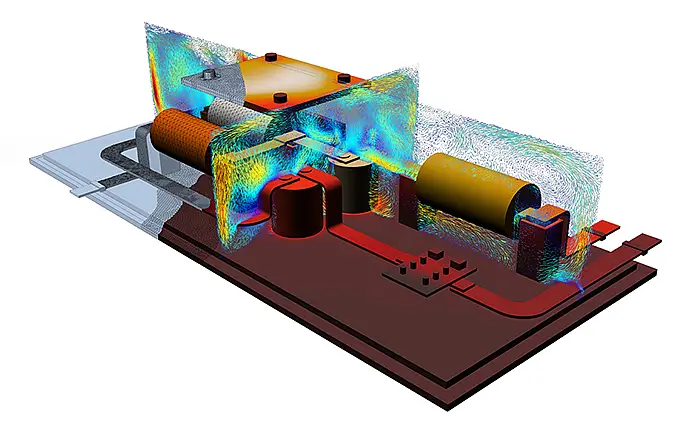

Our thermal management simulations enable you to safeguard your cooling and heating circuits at an early stage. We model flows, multiphase processes and heat transfer in order to design efficient and durable systems.

Read more

Virtual climate change and temperature tests realistically simulate loads caused by changing environmental conditions. This allows weak points to be identified and secured before the physical test.

Read more

We use simulation models to predict material stresses and reactions in the event of sudden temperature changes. This increases safety and reduces expensive iterations during testing.

Read more

From 1D system analyses to FEM and CFD multiphysics: we use a wide range of methods to test concepts virtually. For us, simulations are the key to more efficient development processes and more robust results.

Read moreSimulation as the key to resilient developments

At PTS-Prüftechnik, simulation accompanies the entire development process - from battery cells and assemblies to complete systems. We test concepts virtually, detect weak points at an early stage and secure systems against real loads.

In close connection with engineering and testing, this creates an end-to-end process: simulation shortens development times, makes testing more efficient and provides forecasts that our customers can rely on.