Simulation meets reality

Test virtually. Decide with confidence.

Digital precision and physical know-how: Our multi-physical simulations provide clear answers to complex questions - quickly, soundly and closely linked to the real test.

Physics that thinks ahead

Virtual development at the highest level

Using 1D simulation, CFD multiphysics and FEM, we simulate the behavior of your systems under realistic conditions - from thermal energy flow and electrical reaction to mechanical stress or fluid-dynamic interaction. Our models shorten development times, reduce testing costs and create transparency in early phases. In this way, we digitally ensure functionality, performance and safety - reliably, reproducibly and scalably.

What sets us apart

Fast & reliable results

From the component to the complete system

Seamless connection of simulation & test

Everything from a single source

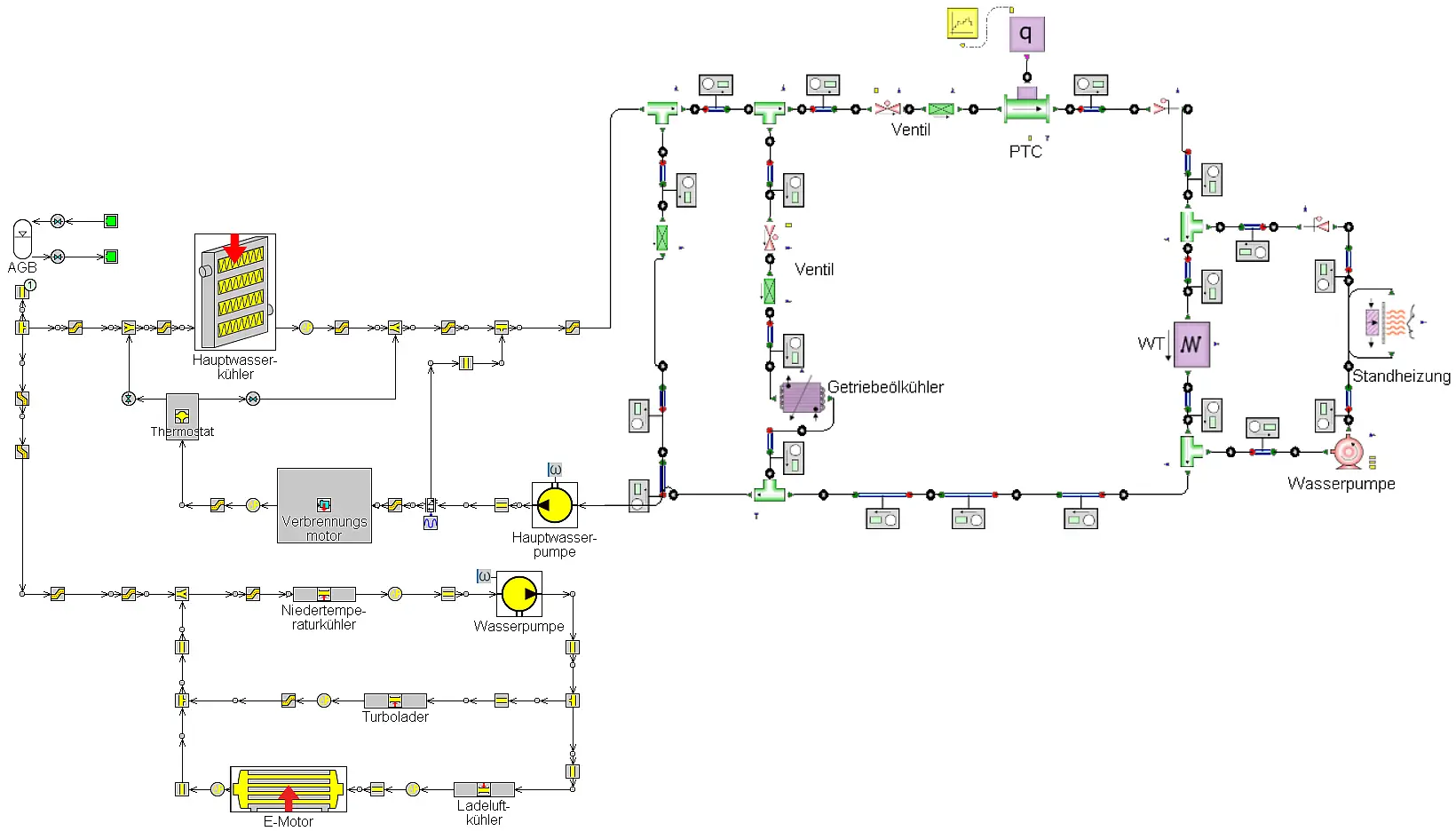

1D simulation

Thermal, electrical, control technology - fast, efficient and realistic

We use 1D simulation to analyze physical systems with minimal computing effort - ideal for cooling circuits, wiring systems and controlled systems. Our models can be used flexibly, can be combined and enable variant comparisons and system optimizations as early as the concept phase.

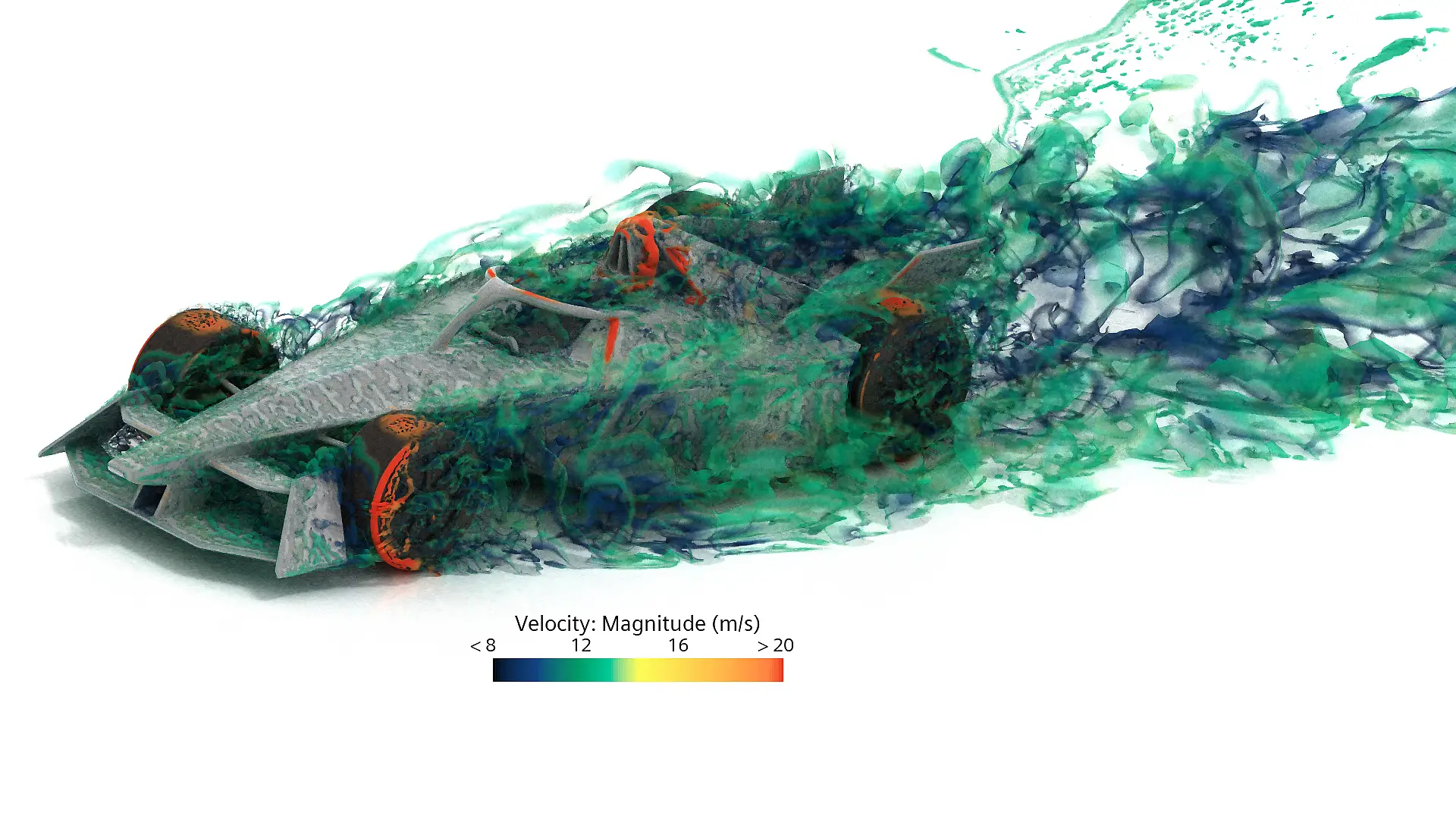

Read moreCFD multiphysics

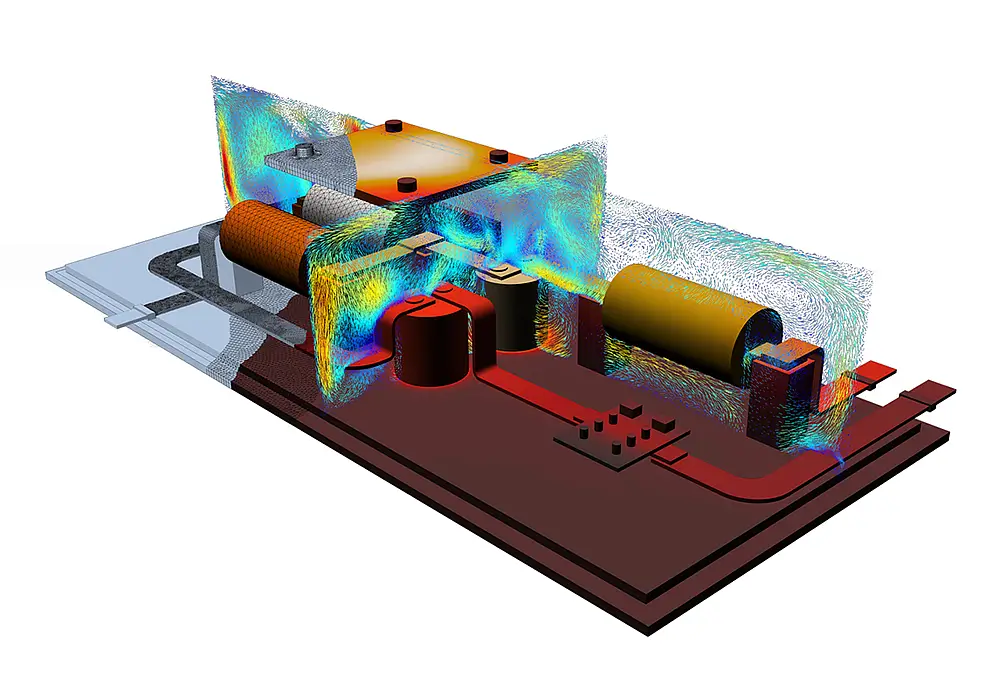

Flow, heat, particles, structure - all in one model

Our CFD models precisely reproduce flow-relevant processes - including heat transfer, phase transformation and particle behavior. Coupled multiphysics approaches also allow fluid-structure interactions and electrothermal effects to be investigated realistically. This produces reliable results for thermal management, air flow and filtration processes.

Read more

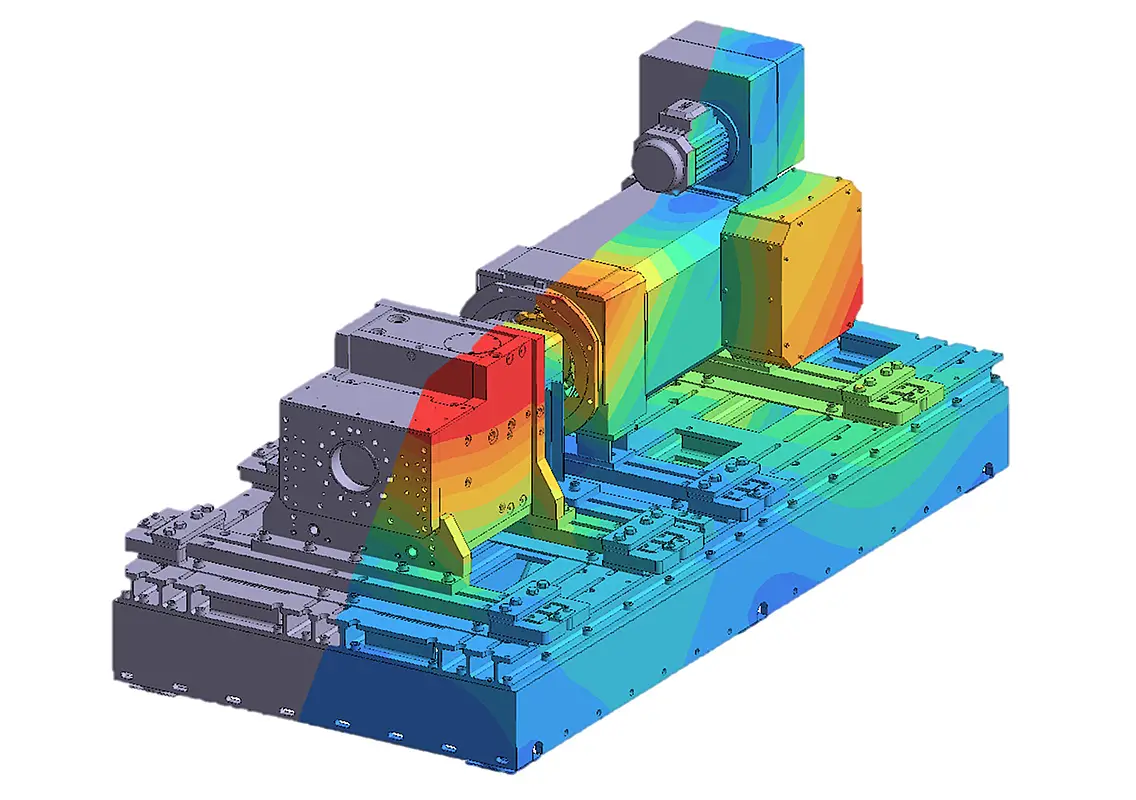

FEM simulation

Understanding, optimizing and securing mechanical loads in accordance with standards

We use the finite element method (FEM) to calculate stresses, deformations and vibrations under static and dynamic loads. Strength, service life and thermal effects are realistically evaluated in order to optimally design and improve your components - from the concept phase through to operational stability.

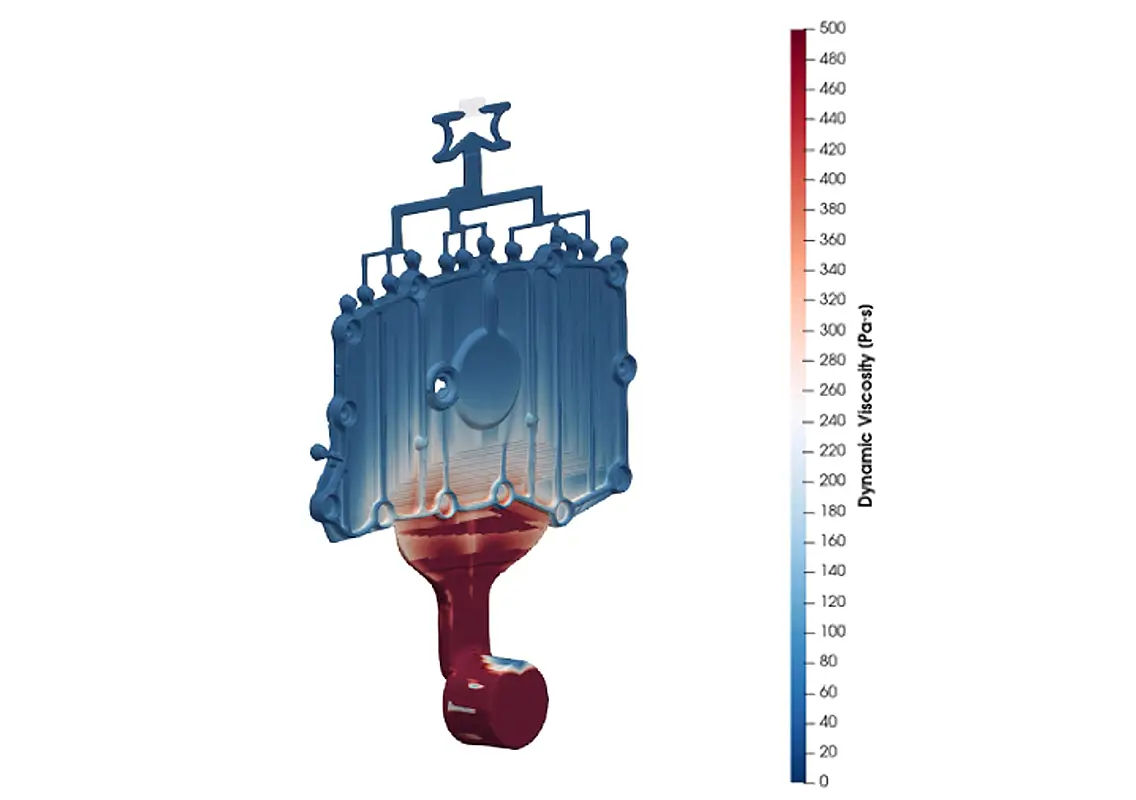

Read moreCasting process simulation

Understanding casting processes, optimizing components in a targeted manner

With FLOW-3D Cast, we simulate mold filling, solidification and porosity - for efficient, safe and reproducible casting processes. Our analyses provide valuable insights into castability, material distribution and process stability, enabling early optimization of component geometries and tool designs - before the first shot is fired.

Read more

Our simulation environment

Powerful tools for precise, flexible models

Depending on the task at hand, we rely on specialized software platforms to ensure the best model quality with maximum efficiency:

StarCCM+ for coupled CFD, thermal and particle analysesOpenFOAM for flexible, open-source flow simulationsCOMSOLMultiphysics for electrothermal, multiphysical and structural-mechanical couplingsFLOW-3DCast for precise and meaningful mold filling and solidification simulations Die casting / permanent mold casting / semi-solids

Our experts select the optimum tool for your requirements - methodologically reliable, tried-and-tested and expandable at any time.

Innovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.