Casting process simulation

Digitally secured casting processes

We simulate and optimize casting processes - from feasibility analysis to process validation. With FLOW-3D Cast, we realistically simulate mold filling, solidification and porosity and thus support the efficient development of aluminum and magnesium components.

Precision right from the start

From virtual model to series production

Casting process simulation is a key tool for the design and validation of light metal casting processes. By combining simulation, engineering and consulting, we ensure quality, reduce rejects and shorten development cycles - for reliable results in die casting, low-pressure die casting and semi-solid casting processes.

Our services at a glance

We support you from the initial concept phase through to series production - with comprehensive simulation and process consulting.

Main focus:

- Technical and economic evaluation of casting processes

- Precise modelling and visualization with FLOW-3D Cast

- Development of casting systems incl. pressure and vacuum venting

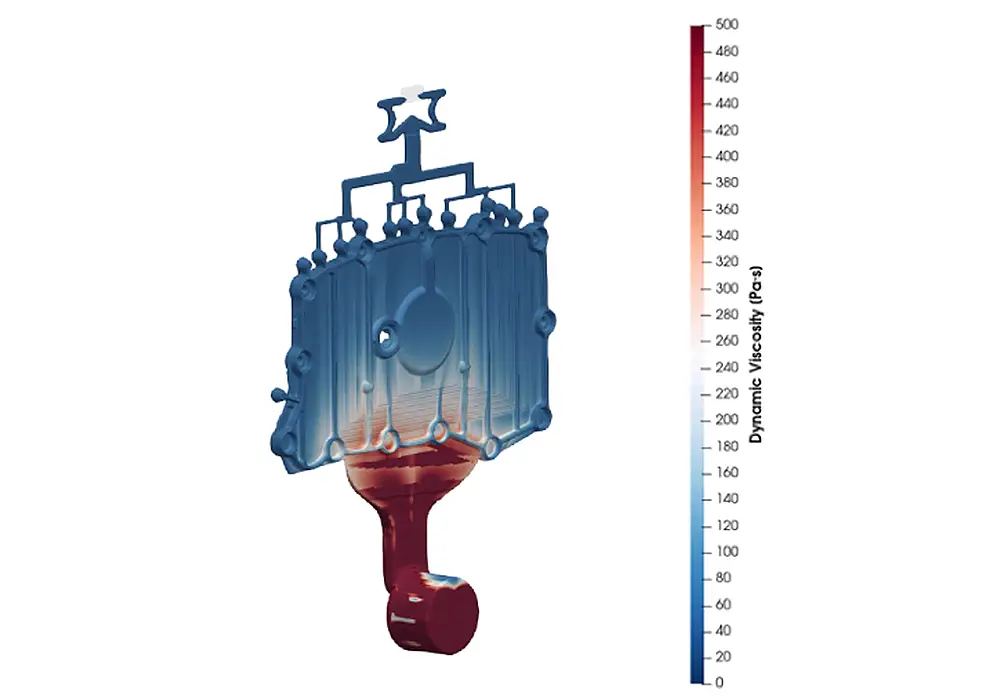

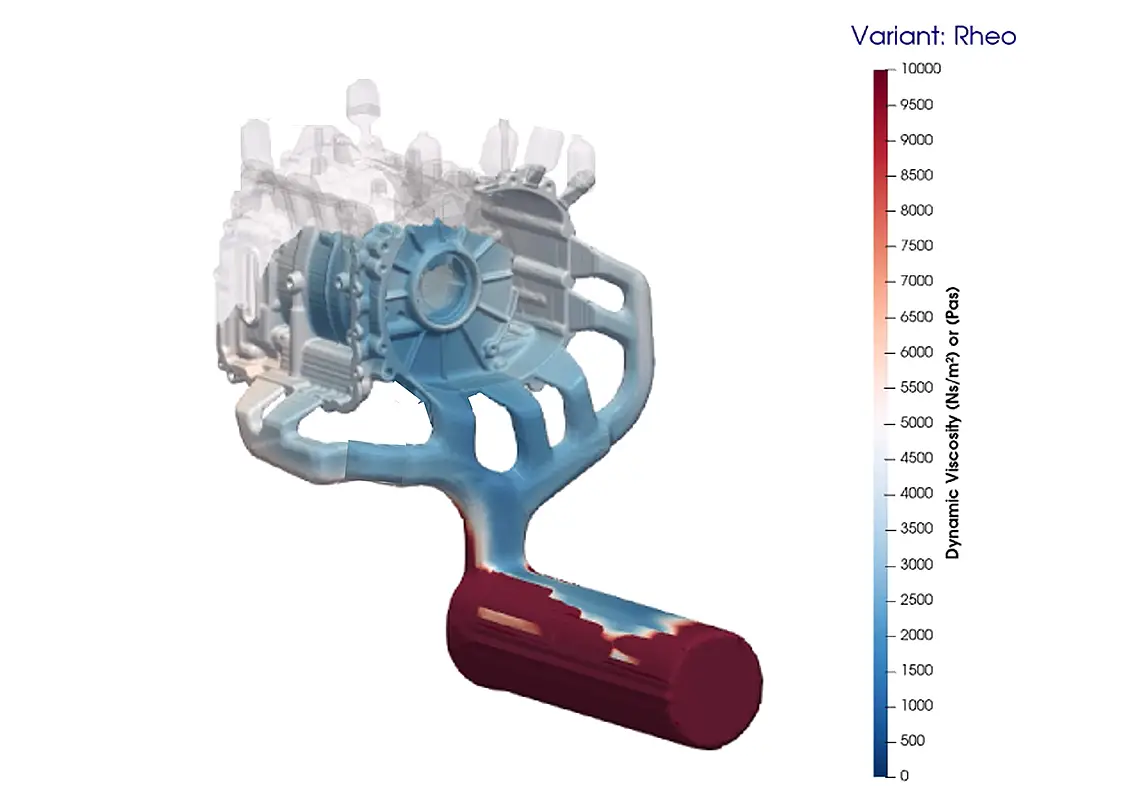

- Realistic Semisolid mold filling and solidification simulation with PTS-Semisolid-Solver under FLOW-3D Cast

- Production-oriented design optimization of the casting

- Simulation of aluminum and magnesium casting alloys

- Process development for cast components - also large-format and/or thin-walled

We analyze existing casting processes, identify weak points and support the rapid implementation of improvements - on site or digitally.

Focus areas:

- Troubleshooting and root cause analysis

- Reduction or elimination of casting defects

- Scrap reduction and process optimization

- Analysis of the entire process chain: melt, casting mold, heat treatment, joining and coating

- CaaS - Consulting as a Service: flexible, demand-oriented consulting with short response times based on a subscription model

Innovative processes rethought

Semisolid casting process development in focus

Using PTS's own semi-solid solver integrated in FLOW-3D Cast, we simulate mold filling and solidification for various semi-solid casting processes. From process design and procurement of production equipment to initial sampling, we accompany the entire process right through to series release. The result: reduced cycle times, increased output per mold, higher overall system efficiency and high casting quality.

Advantages

Fast & reliable results

From the component to the complete system

Seamless connection of simulation & production

Everything from a single source

Assemblies & components

Mechanical, electrical and hydraulic tests for a wide range of applications >

Read moreCasting process simulation as part of our simulation world

Digitally safeguarding casting processes

Casting process simulation complements 1D, CFD and FEM methods and expands digital development to include mold filling and solidification. This allows casting processes to be evaluated at an early stage, components to be optimized in a targeted manner and production risks to be minimized. Together with our other simulation focal points, a continuous, virtual development process is created - from the idea to series production

Explore the full Simulation portfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.