Clutch and brake systems put to the test

Safety that stands the test of time

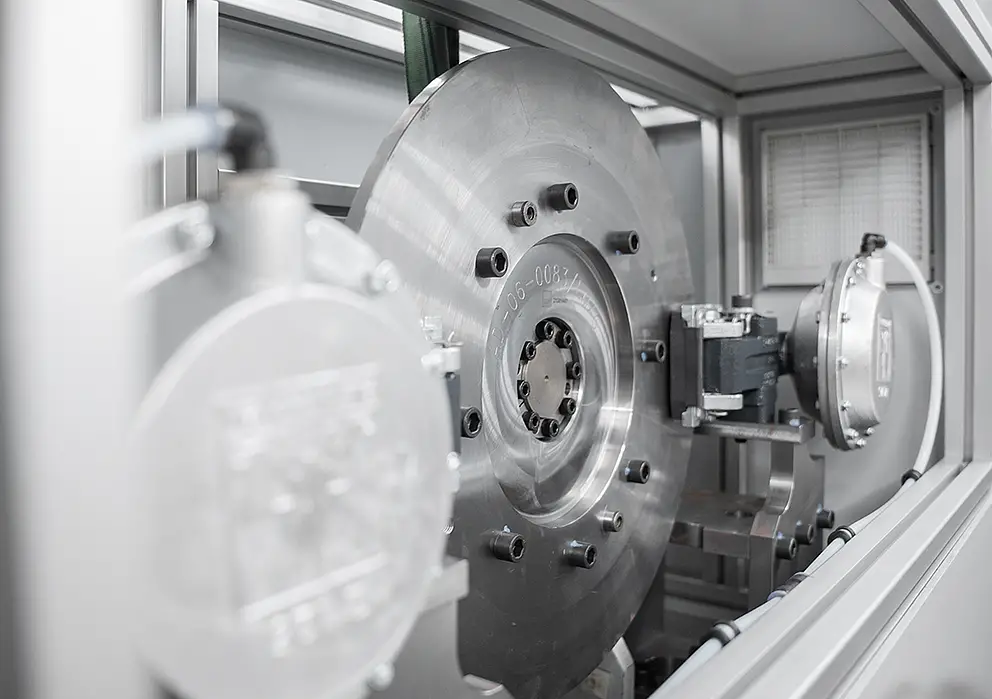

From precise control to emergency stops: clutch and brake systems must work perfectly in every situation. Our tests combine mechanical, thermal and hydraulic tests to ensure long-term performance and safety.

Focus on comfort and reliability

Function that convinces

Separate, connect, decelerate - clutch and brake systems are crucial for control and driving feel. PTS-Prüftechnik develops tailor-made test set-ups, analyzes friction behavior, evaluates seals and simulates real load curves. Whether it's a wear test or series approval: we deliver reproducible results for your safe decision.

Realistic load. Precise evaluation.

Our test setups measure the frictional contact precisely - for reliable statements on function, service life and quality.

Scope of services:

- CFD-supported test box design

- Shifting & braking cycles with real friction partners

- Endurance & wear tests

- Online monitoring with O.K./N.K. evaluation

- EOL acceptance tests with series reference

Test your systems under real friction conditions - reproducible and automated.

From coefficient of friction to releaseOurtribological tests are seamlessly linked to the test: We analyze microstructures, check dimensional accuracy and evaluate thermal or mechanical damage - documented in a traceable manner.

Analysis methods:

- Microscopic structural comparisons and material analyses

- Dimensional inspection of lamellas and linings

- Assignment to O.K./N.K. criteria for series approval

Recognize wear limits at an early stage - for reliable approvals and reduced development cycles.

Everything for reliable results

Test specimens & infrastructure at a glance

Typical test specimens:

Our tests cover all safety-critical components:

- Clutch disks, linings, plates

- brake calipers, pads, brake discs

- seals, pistons, pressure plates

Technical infrastructure:

We rely on versatile equipment for reproducible tests:

- In-house developed test boxes with CFD calculation

- 3D-printed adapters & test carriers

- Climatic chambers (-70 °C to +240 °C)

- High-resolution sensors

- Automated test bench control & evaluation

- Tribological laboratory findings

Advantages

Holistic system testing

Real test conditions

Customized tests & analyses

Everything from a single source

Clutch & brake systems in powertrain testing

More than brake and clutch tests

Clutch and brake systems are just one part of our powertrain portfolio. We test the entire powertrain - including power electronics, transmission and electric drive units - under realistic driving and load profiles.

Explore the full Powertrain Testing portfolioInnovative development for future-proof drive systems. We combine technical know-how with practical implementation.

Virtual tests for precise and efficient solutions. This is how we optimize systems already in the early development phase.

Comprehensive testing procedures for maximum safety and performance. We test under real conditions for reliable results.